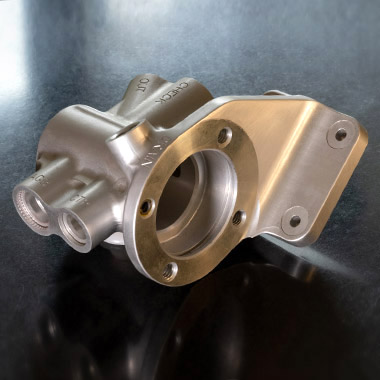

Our new Mazak QUICK TURN 250MSY CNC Turning Center with Multi-Tasking capability brings together advanced technology, productivity and value to deliver exceptional performance. The machine features milling and Y-axis capability as well as a second turning spindle to process parts in DONE IN ONE® operations. This functionality enhances both production speed and accuracy. In addition, the direct-drive turret features increase rpm and eliminates the use of belts for improved part surface finishes and reduced maintenance.

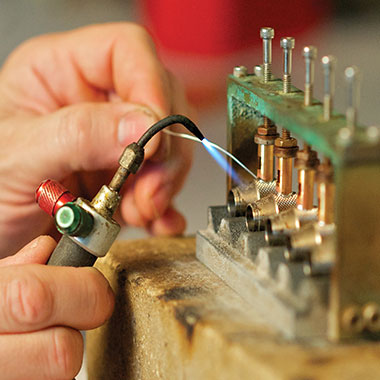

At Antron Engineering we are driven to stay on the cutting edge of precision machining and assembly. Whether it’s the latest turning tools or updated job tracking software we constantly review and update our entire facility to make sure we have what it takes to get your job completed to your exact specifications.

AS9100D/ISO 9001-2015 Certificate

View certificate for printing.

ISO 13485/2016